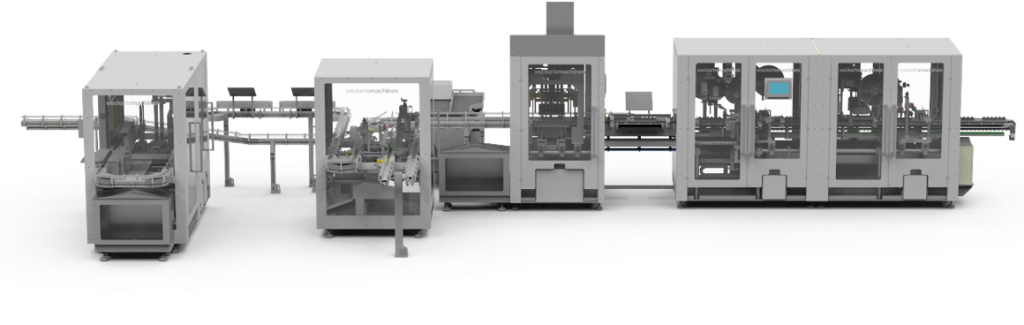

FAL

Flexible Assembly Line

Options for Upstreaming i.e. for base/bottle or cap/applicator feeding

- FlexFeeder with up to 180pcs/min throughput – bulk or tray delivered

- Tray tower system especially for high-class and scratch-sensitive products

- Plate feeding system for a cost-efficient solution for bulk-delivered products

- Linmot or servodriven controlled positioning of the products

A high automization will reduce the cost per piece, adds stability and reliability to the process and makes your production efficient.

Features

- Buffer solutions for up to 800 products

- Standard labelling units for bottom, wrap-around and / or side labels

- Servodriven sleeving unit for all kind of products up to 60 ppm

- Integration of Cartoning machines or product hand-over to other machines

- Quality control by manual or automatic camera inspection

- Torque controlled wind down or positioning of a product

- Flaming module (infrared or gas) to reach special surface finishes

- Laser coding/ink jet coding

We provide tailor made solutions for you!

For detailed information and a specific offer please get in contact with us.